Gas Turbine Combustion

Direct-fired supercritical carbon dioxide (sCO2) power cycle

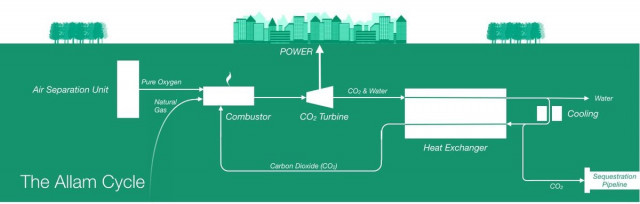

The supercritical carbon dioxide (sCO2) power cycle (e.g. Allam cycle) with direct fired oxy-fuel combustion is one of the most promising alternatives to conventional power generation cycles due to its high efficiency and zero emissions. Unlike conventional power generation plants, the Allam cycle is characterized by high efficiency and no pollutant emissions such as NOx and SOx. This is because the gas fuel is burned with pure oxygen generated from an Air Separation Unit (ASU) and the cycle is operated under supercritical conditions. Since sCO2 is the working fluid, we can significantly reduce inefficient power losses in the steam condensing process in the stream cycle (Rankine cycle) and the compression process in the gas turbine cycle (Brayton cycle). In 2017, NET Power, the first Allam cycle power plant, was built in Texas.

<The first Allam cycle power plant, source: https://www.inc.com/kevin-j-ryan/net-power-zero-emissions-plant-global-warming.html >

<The first Allam cycle power plant, source: https://www.inc.com/kevin-j-ryan/net-power-zero-emissions-plant-global-warming.html >

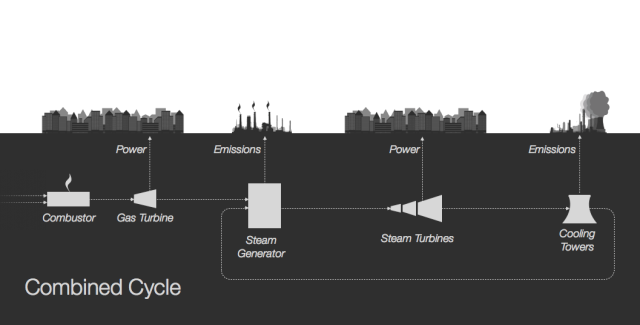

<Combined cycle schematic, source: NET Power, https://www.netpower.com/ >

<The Allam cycle schematic, source: NET Power, https://www.netpower.com/>

Advantage of the Allam cycle power plant

- High efficiency (power loss reduction by avoiding condensing process in conventional steam cycles)

- Zero atmospheric emissions (NOx and SOx free)

- Low cost (Do not need a complex NOx emission reduction equipment)

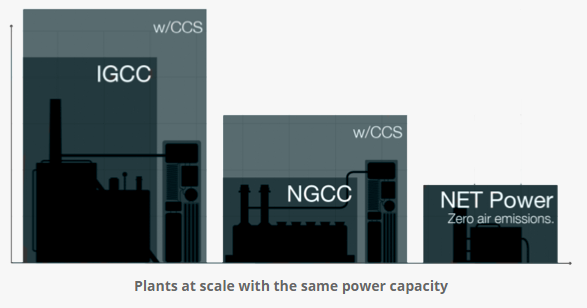

- Simpler and smaller plants compared to conventional ones such as IGCC (Integrated Gasification Combined Cycle), NGCC (Natural Gas Combined Cycle), and so on.

<Comparison with different kinds of power plant such as IGCC(Integrated Gasification Combined Cycle), NGCC(Natural Gas Combined Cycle), and NET Power(Allam Cycle), source: NETPower, https://www.netpower.com/>

- High-quality CO2 byproduct without additional carbon capturing equipment

- Low water usage (since the working fluid is sCO2 and water is used only for cooling the system)

What we do?

- Development of a numerical code using OpenFOAM for the direct fired oxy-fuel combustion simulation in the supercritical carbon dioxide (sCO2) power cycle conditions

- Optimization of a numerical code

- NOx emission characteristics of sCO2 power cycle

- Various numerical simulations in the sCO2 power cycle conditions

Plasma-assisted combustion

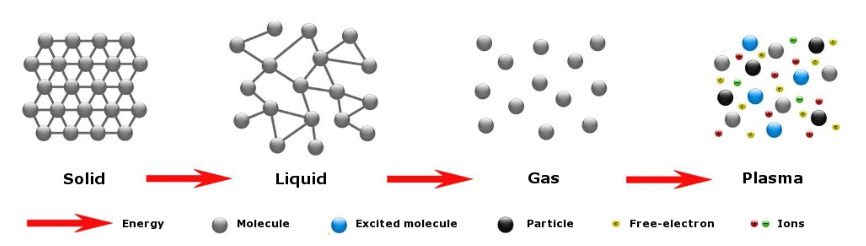

What is plasma?

plasma is one of the four fundamental states of matter and can be artificially generated by heating or subjecting a neutral gas to a strong electromagnetic field to the point where an ionized gaseous substance becomes increasingly electrically conductive, and long-range electromagnetic fields dominate the behavior of the matter.

<The Sun, a matchless laboratory for the study of plasma physic, http://www.astropa.inaf.it/en/luglio-2017-la-ricerca-in-evidenza-il-sole-un-laboratorio-unico-per-la-fisica-del-plasma/>

Development of novel technology for the reduction of pollutant emissions in gas turbine combustor: plasma

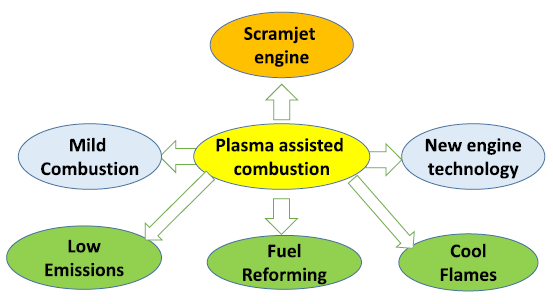

During the past two decades, plasma has emerged as one of the promising techniques to enhance combustion, reduce pollutant emissions, and control combustion instability. Many studies have successfully demonstrated that NOx and/or particulate matters (PM) emissions can be significantly reduced by utilizing various types of plasmas such as gliding arcs, pulsed corona discharge, and dielectric barrier discharge (DBD). Especially, the applicability of non-thermal plasma (NTP) such as microwave discharge and DBD to combustion systems has been investigated because it has relatively low cost and power consumption compared to thermal plasma.

<Schematic of plasma assisted combustion and applications, Y. Ju, W. Sun, Progress in Energy and Combustion science 48 (2015) 21-83>

Non-equilibrium plasma and the effect of plasma on combustion

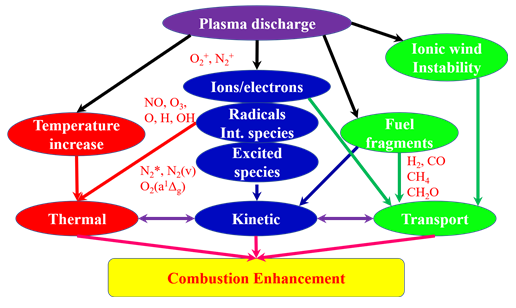

There are three major enhancement pathways of plasma interaction with combustion.

- In the thermal enhancement pathway, plasma can increase temperature and accelerates chemical reactions and fuel oxidation according to the Arrhenius law.

- In the kinetic enhancement pathway, plasma generated high energy electrons and ions will further produce active radicals through direct electron impact dissociation, ion impact.

- In the transport enhancement pathway, plasma can breakdown the fuel molecules to fuel fragments with changing the fuel diffusivity that modifies the combustion process

<Possible combustion enhancement pathways of plasma assisted combustion>

Plasma-assisted combustion for flame stabilization in the gas turbine combustor

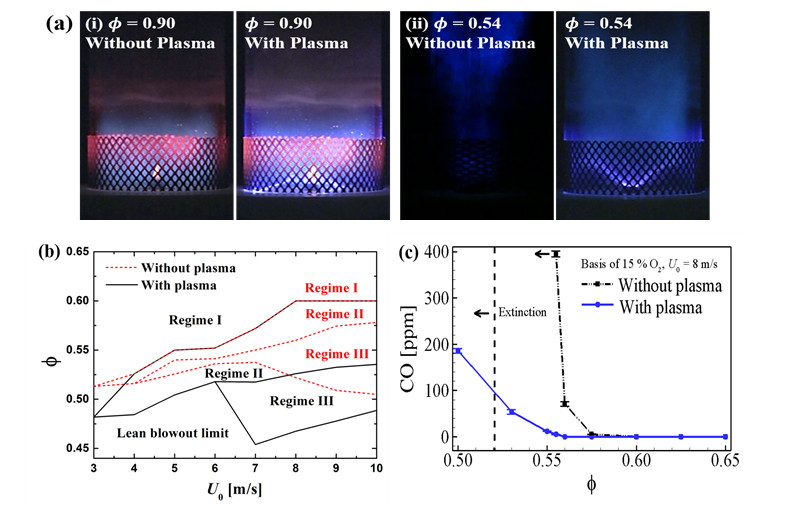

From our previous study, it was found that non-thermal plasma can extend lean blowout limits and reduces CO emission by enhancing combustion.

<(a) Flame images without and with plasma at equivalence ratio 0.90 and 0.54, (b) flame regime diagram of extension of lean blowout w/o plasma limit, and (c) the emission of CO w/o plasma, submitted, 2019>

<(a) Flame images without and with plasma at equivalence ratio 0.90 and 0.54, (b) flame regime diagram of extension of lean blowout w/o plasma limit, and (c) the emission of CO w/o plasma, submitted, 2019>

What do we do?

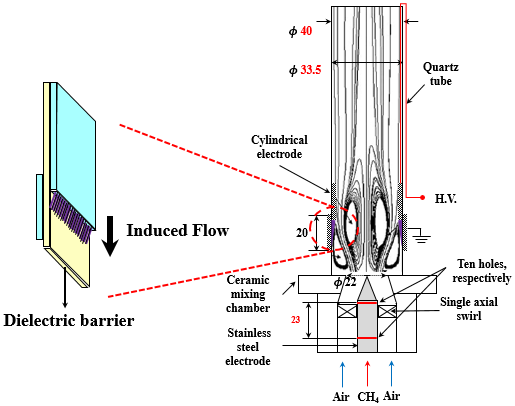

The plasma layer provides, through Lorentzian collisions, a purely electrohydrodynamic coupling between an electric field and the neutral gas in the boundary layer, using surface dielectric barrier discharge (SDBD). This coupling is strong enough to cause aerodynamically significant acceleration and manipulation of the boundary layer and free stream flow, controlling inner and outer recirculation zones.

Two-Stage Model Gas-Turbine Combustor

What is staged combustion?

Staged combustion is a combustion method that reduces pollutants including NOx by air staged supply or fuel staged supply.

Advantage of the Two-Stage Model Gas-Turbine Combustor

- High efficiency (power loss reduction by avoiding condensing process in conventional steam cycles)

- Zero atmospheric emissions (NOx and SOx free)

- Low cost (Do not need a complex NOx emission reduction equipment)

- Simpler and smaller plants compared to conventional ones such as IGCC (Integrated Gasification Combined Cycle), NGCC (Natural Gas Combined Cycle), and so on.

What do we do?

To investgate the combustion and emission characteristics of turbulent CH4/NH3/air premixed flames in both single- and two-stage model gas turbine, 3D LESs were conducted, focusing on the effect of the secondary air injection location.

3D volume rendering of OH radicals for single-stage combustion cases and two-stage combustion cases